for tight bends I bent some steel round one end similar to a conduit bender pivot.

Keep matching it against a form that you want it to match. Fasten two 9" diameter to the sides looks like a pulley. glue up 1/4" to the 3/4) and 7" in diameter. I cut 3/4" plywood into three half circles. I bent them, and they came out very nice on a wood mandrel I made. The bows are 44.5" wide and matched the curve of the Plexiglas. 049 square tubing for the canopy Needed two bows and the instrument panel.

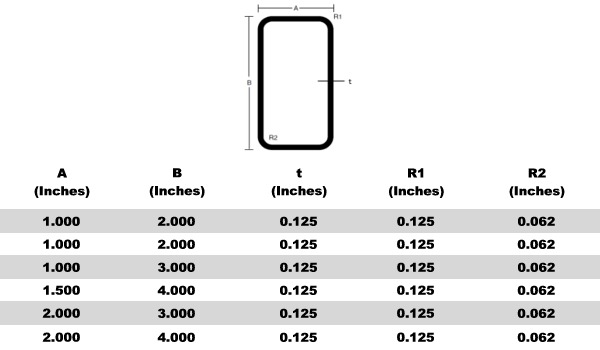

Length of bend - equation for length of arc, based on bending radius through centerline a. Bend angle - number of degrees greatly affects raw material calculations 5. Still need the parts, project completely stalled till I do.Ĭan anyone in this forum point me to a company local or even not local that can do the job? Or identify a tool or method that I can use to bend these myself? Radius of bend - decided by the space the part fits in, dies available 3. I sent a part sample as pattern before Christmas and now I can not get them to answer emails or phone calls. My first choice, have Aero Adventure (FL) do the job, they said they can. Helens OR that advertised mandrel tube bending and they just told me "no can do". As this sort of thing quite common on many ultralight designs, I figured living in Portland metro area home of Van's aircraft and several other kit aircraft businesses, I should have no problem finding a shop to bend thin wall aluminum tube. several tight bends required in 6061-t6 1" dia, 0.049" and 0.065" thick walled tubes. Have several parts to fabricate for a Buccaneer 2 project. If they can't do the work, they should know who will. If you have multiple options, optimize your choice.Find yourself a local hydraulic supply house.You may choose any bend radius on this line(s).Consider what minimum bend size you require (Only consider lines that meet your minimum bend requirement).Refer to the first column to choose your material thickness.Refer to table(s) for your choice of material.So in this case, the minimum inside bend radius is 2 times the material thickness. Now, multiply that answer by the plate thickness. Next, subtract 1 from that answer: 5 1 4. It is possible to choose other bends, but tooling charges may apply. If the steel has a tensile reduction value of 10 percent, divide 50 by that value: 50/10 5. The tables below show bend radii and minimum bend sizes for materials and tooling combinations stocked by Protocase. Alternatively, you can design with any value, and we can adjust it for you later in the process. If you need help choosing a value, contact us at or 1-86 and we can help. However, the most common ones are usually in line with specific rules of thumb. Bend radius tooling often differs, depending on the tube bender. The bend radius of a tube is the radius measured to the tube’s centerline. Use this document to choose values that are both manufacturable and meet your needs. Stainless Steel Tubing Bend Radius Chart. It is most economical to use a single bend radius throughout the design, but if necessary, you can utilize multiple radii. ( Watch More Tech Tip Videos) Bend Radii & Minimum Bend Sizes

0 kommentar(er)

0 kommentar(er)